Legos on the Moon?

The building blocks are being tested in space right now

September 1, 2021

It’s expensive to take stuff to space. Weight is the enemy of breaking the bonds of gravity. One needs a massive rocket with a relatively small capsule on top that can carry cargo and humans.

The U.S. made it work on the Apollo missions. The astronauts lived for a few days in the spacecraft they used to land on the surface of the moon. But as you have seen here before, the U.S. intention is to stay on the moon and build a base.

Artist depiction of astronauts working in the surface of the Moon. (Credit: NASA)

The astronauts will not be taking concrete to build their moonbase (they won’t be using Legos either). Instead, NASA wants to use what is already on the surface which will make it easier and cheaper to build a base.

The U.S. plans to return to the moon will take astronauts to the lunar South Pole. NASA hopes to find ice that can be used to make water and fuel for rocket engines.

As for structures, the hope is to use the regolith on the surface. Regolith is neither soil, nor sand, but “a layer of unconsolidated rocky material covering bedrock,” according to the Oxford dictionary. There is a lot of it on the moon.

Artist rendering of moonbase concept. (Credit: ICON)

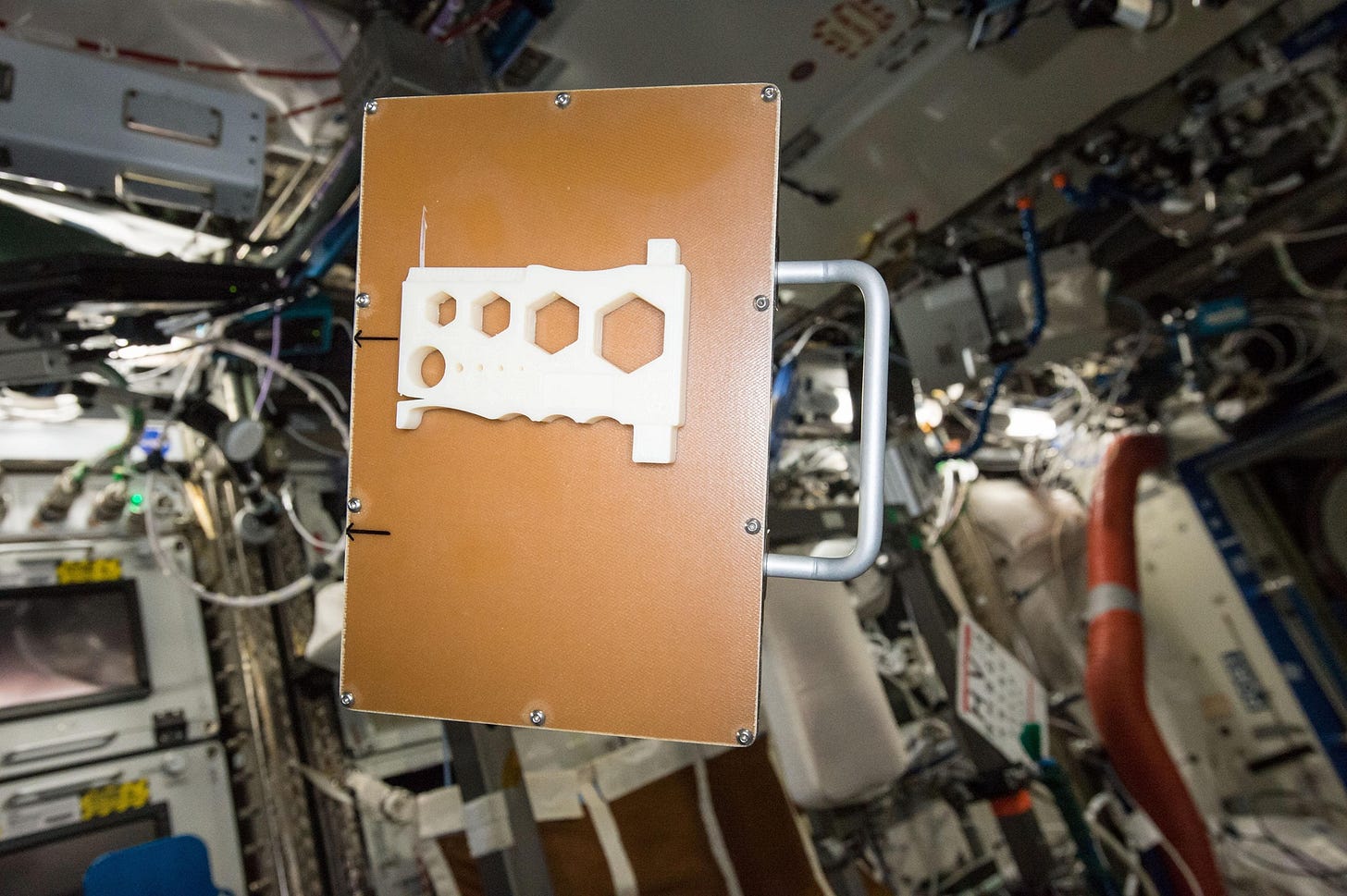

Scientists are working on ways to “consolidate” that rocky material and build structures. Think of making mud. Take some dirt, add some water and the material sticks together. In August an experiment was flown to the International Space Station to test a 3D printer with an all-important “binder” that can hold the regolith together.

NASA, the European Space Agency (ESA) and plenty of companies have been working on 3D printed structures for years now. One experiment, built in a NASA warehouse in Houston, will be occupied by volunteers for a year. It’s a print crew quarters and workspace. This follows a NASA challenge years ago in which universities and companies created systems and structural designs that have moved the work forward.

(Credit: ICON)

That’s why this current experiment on the Space Station is so important. Scientists have been using a simulated regolith with a binder here on Earth and it works great. But what about in space or on the surface of the moon where gravity is one-sixth of that on earth? That’s why astronauts will install the experiment. Three samples will be produced and then brought back to Earth to learn if the binder holds.

A 3D print experiment on the International Space Station (Credit: NASA)

NASA’s Marshall Space Flight Center is working with Redwire, a Florida company, one of several working on manufacturing systems for space and celestial bodies. Redwire’s Chief Technology Officer Michael Snyder says they will be testing three different printer heads with different samples. Snyder says they are working on a binder for the cold of the South Pole, “all the way up to a binder that can survive a lunar day fully exposed without any problems.” He adds, ”it’s a really, really volatile and extreme environment.”

The plan is that once these systems and binders are developed and proven, robots will be sent to the moon well ahead of astronauts. The robots will start printing (building) structures the astronauts can use. The ESA has produced a video that provides one of the many ideas for printing with regolith.

Animation of 3D printing on the surface of the Moon. (Credit: ESA & Foster+Partners)

They really aren’t legos. It’s more like squeezing a tube of concrete and layering it on top of another squeeze of material. ICON, the company that built the structure for NASA in a warehouse, uses a similar system to build homes here on earth.

(Credit: ICON)

While the regolith may not snap together, these are the building blocks that may allow astronauts to return and stay on the surface of the moon.

(Credit: ICON)