September 26, 2021

The headlines have been relentless in declaring a chip shortage. It’s led to fewer new cars being made as well as consumer electronics including gaming consoles. What the heck is this chip shortage and how do we get out of it?

CHIPS

Chips, in this case, are not Doritos or french fries in England. They refer to semiconductors, the small devices- many made on silicon wafers- that control the flow of electricity and are the building blocks for most of our electronic gadgets. Chips are small, efficient, and reliable. They must be made to exacting standards in order to work properly.

(Credit: SEMI)

SHORTAGE

This has been the year of the chip shortage and there are a number of causes. Some chip plants were shut down by natural disasters. The COVID pandemic robbed other manufacturing plants of their workers for a period of time. But the semiconductor industry says it is really more about supply and demand.

When the pandemic hit in 2020, automakers saw consumer demand for new vehicles drop off a cliff. Those car companies canceled their orders for chips that help control more and more of the systems in their vehicles.

At the same time, with so many people at home quarantining, the demand for laptops and video gaming consoles skyrocketed. So what did the chip makers do? They changed their production lines to make the chips for the computer and game console makers.

(Credit: SEMI)

With vaccines arriving in early 2021, the automakers started ordering chips again to meet the suddenly growing demand for new vehicles. The entire auto industry accounts for only 10% of all chips made worldwide- not a lot of leverage. The chip makers couldn’t fill all those auto industry orders because they were already at near full capacity for the computer and gaming console industry. That led to this chip shortage.

INCREASING PRODUCTION

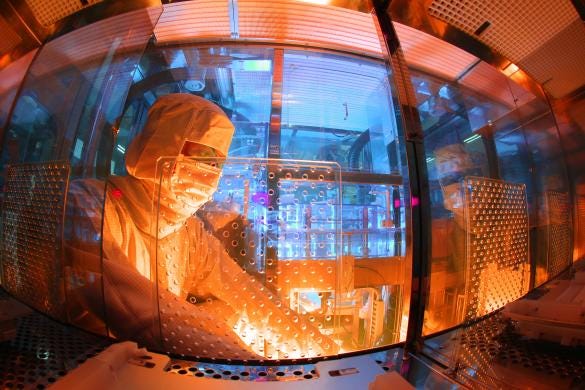

Making chips is not like general manufacturing. Production lines cost tens of millions of dollars. “It's not like manufacturing a molded plastic part that you can mass produce relatively quickly. The semiconductor industry might be the one of the most sophisticated, most complex production businesses in the world,” says Bettina Weiss, Chief of Staff and Global Smart Mobility Lead for SEMI, the association representing chip makers.

SEMI Chief of Staff and Global Smart Mobility Lead (Credit: SEMI)

Chips for the auto industry are not the same as those built into a laptop. The automobile chips have to stand up to high temperatures and last the life of a vehicle. “There's an entire line of equipment and processing technology going into the making of one particular chip that doesn't lend itself to a lot of agility,” Weiss told me.

INCREASING CAPACITY

There is some good news. The chip industry is spending to build new production lines and the shortage may start to wane later this year and into 2022. “We have more capacity coming online, there are dozens of new facilities being built. But that's anywhere from two to four years or so until we really see a massive uptick in capacity,” say Weiss.

(Credit: SEMI)

But that raises new concerns for the chip makers. If they spend all those millions of dollars to increase production, will they end up with a glut of chips? The risk of overcapacity is real, says SEMI.

There are plenty of lessons here, and dramatic changes are being made by some automakers and the US government. More on that in the next newsletter.